In every industrial sector, whether manufacturing, energy, or engineering, accurate measurement is the foundation of quality and reliability. Even the most advanced equipment can lose accuracy over time due to wear, environmental conditions, or regular use. That’s where calibration comes in. This blog explains why regular calibration is essential for accurate industrial measurements, how it ensures consistent performance, reduces costly errors, maintains safety standards, and helps businesses comply with quality regulations. By the end of this article, you will understand the critical role of calibration in maintaining precision, safety, and trust across industrial operations.

Understanding Calibration and Its Importance

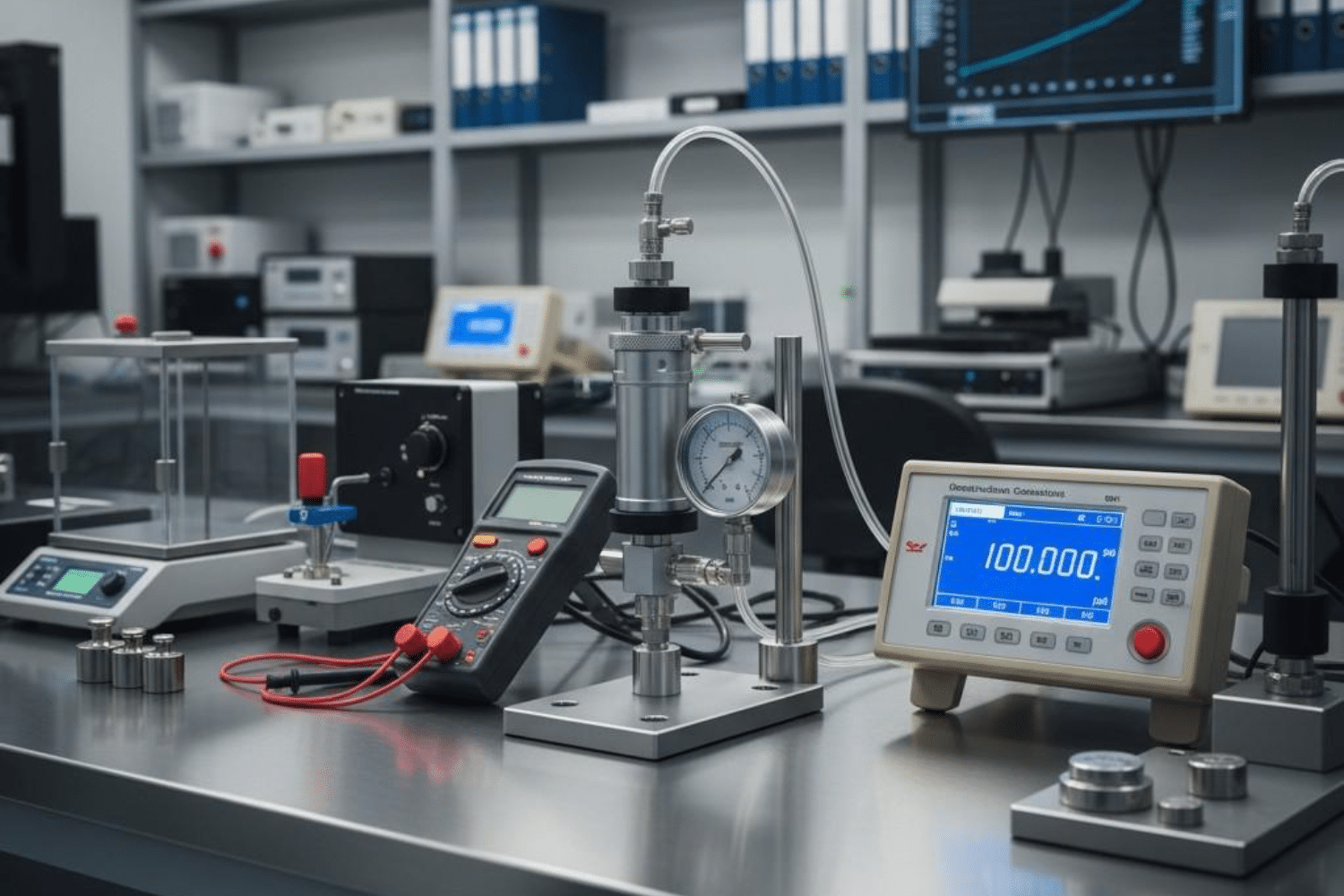

Calibration is the process of comparing a measuring instrument’s readings with a known standard to determine its accuracy. If discrepancies are found, adjustments are made to bring the device back within the acceptable range of precision.

In simple terms, calibration ensures that the measurements you rely on for production, safety, and quality are accurate, consistent, and trustworthy. Without regular calibration, even small deviations in readings can lead to serious errors in industrial processes, from product defects to safety hazards.

Why Accuracy Matters in Industrial Settings

Industries depend on measurement instruments for a wide range of operations, including temperature control, pressure monitoring, flow measurement, and electrical testing. When these instruments provide inaccurate readings, it can affect:

- Product quality: Incorrect measurements can lead to manufacturing errors or defective products.

- Operational efficiency: Inaccurate data can result in wasted materials or time.

- Safety: Unreliable instruments can create unsafe working conditions or equipment failures.

- Regulatory compliance: Many industries must meet international quality and safety standards.

Accuracy ensures smooth operations, protects resources, and builds customer trust.

Common Causes of Measurement Inaccuracy

Even the best instruments can lose accuracy over time due to various reasons:

- Wear and tear: Frequent use or mechanical stress can affect sensors and components.

- Environmental factors: Humidity, temperature fluctuations, and dust can alter readings.

- Aging of equipment: Components naturally degrade over time, leading to drift in measurements.

- Improper handling or maintenance: Mishandling instruments can easily affect calibration settings.

Regular calibration detects these issues early, ensuring that instruments perform as intended.

The Benefits of Regular Calibration

Regular calibration is not just about meeting compliance standards, but it’s about optimizing performance and reliability. Here are some key benefits:

- Ensures Reliable Measurements: Calibration confirms that the instruments are performing within acceptable limits. Reliable data helps teams make informed decisions, reduces uncertainty, and supports efficient operations.

- Maintains Product Quality: In sectors like manufacturing, energy, or engineering, even a minor deviation in measurement can impact the final product’s quality. Calibration ensures consistency, helping businesses maintain a strong reputation and avoid rework or customer complaints.

- Reduces Operational Downtime: Regular calibration minimizes unexpected equipment failures. Identifying potential issues early prevents costly interruptions in production and extends the lifespan of your instruments.

- Improves Safety: Inaccurate measurements can compromise safety. For example, incorrect pressure or temperature readings can cause accidents. Calibration ensures all safety instruments are working correctly, protecting both personnel and assets.

- Supports Compliance and Audits: Most industries follow strict quality assurance and compliance guidelines. Calibration helps meet these requirements by maintaining traceable records that can be presented during audits or inspections.

- Enhances Cost Efficiency: Though calibration involves time and resources, it ultimately saves money. Accurate instruments reduce material waste, minimize downtime, and prevent costly production errors. Over time, this leads to improved profitability.

Key Instruments That Require Regular Calibration

Different industries rely on various measurement instruments that need periodic calibration, including:

- Temperature sensors and thermometers

- Pressure gauges and transmitters

- Flow meters

- Electrical meters and multimeters

- Weighing scales

- Gas detectors and analyzers

Each instrument has its own calibration frequency depending on usage, environment, and manufacturer recommendations.

How Often Should Calibration Be Done?

The frequency of calibration depends on several factors:

- Manufacturer guidelines: Most instruments come with a recommended calibration schedule.

- Usage intensity: Equipment used frequently or in harsh environments needs more regular calibration.

- Regulatory standards: Some industries require calibration at fixed intervals to meet certification requirements.

- Past performance: If an instrument shows signs of drift or inaccuracy, it may need earlier recalibration.

A good practice is to establish a calibration schedule and maintain detailed records for each instrument to ensure consistent accuracy.

Signs Your Instruments Need Recalibration

It’s not always easy to tell when an instrument needs recalibration, but some warning signs include:

- Inconsistent readings over time

- Increased rejection rates in production

- Unexpected deviations from previous measurements

- Visible damage or malfunctioning parts

Addressing these early can prevent larger operational problems later.

The Impact of Neglecting Calibration

Neglecting calibration can lead to significant consequences:

- Product recalls or failures due to poor quality control

- Safety incidents caused by incorrect readings

- Regulatory penalties for non-compliance

- Financial losses from wasted materials or downtime

Ignoring calibration may seem like a small oversight, but its impact can be severe and long-lasting.

Building a Culture of Accuracy and Reliability

Calibration should be part of every company’s quality culture. Training staff to understand the importance of accurate measurement, maintaining calibration records, and scheduling regular checks helps build a proactive, reliability-focused organization.

A well-structured calibration program is a long-term investment in performance, safety, and trust.

Conclusion

To sum up, regular calibration is a commitment to precision, quality, and safety. By ensuring instruments deliver accurate results, businesses can maintain efficient operations, reduce costs, and strengthen customer confidence.

Whether it’s for manufacturing, engineering, or energy systems, every instrument plays a crucial role in achieving reliability and consistency.

At V-Tech Group, we understand how essential accurate measurement is to industrial performance. Our team offers advanced calibration solutions and technical expertise to help industries maintain precision and compliance with the highest standards. With reliable calibration support, you can focus on what matters most, like efficiency, safety, and excellence in every operation. Contact us today to schedule your calibration service or get a quick quote.